The core technology of turbo blowers is air bearing. During high-speed rotation, a hydrodynamic pressure is formed between the shaft and the journal bearing. The air bearing is a non-contact that does not cause friction in the rotor, so suitable for semi-permanent operation because no wear occurs during rotation. Clean air can be produced since air acts as a lubricant instead of oil.

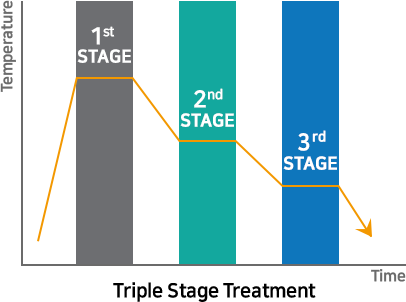

During On/Off

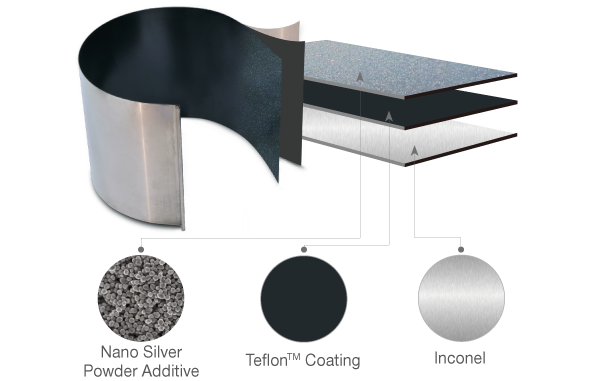

Bearing supports shaft, which forms small preload between the shaft and bearing, and the shaft comes into contact with the journal bearing surface in case of on/off.

Acceleration

When the rotor begins to accelerate, the air foil between the shaft and the journal bearing levitates the shaft by Dynamic Pressure, which generates a Wedge effect.

High Speed Rotation

The support force of the air foil bearing increases in proportion to the rotational speed. At this time, the air foil acts as cooling and lubrication, so continuous operation is possible without additional cooling system.